1. Definition of modular housing

A modular housing is a prefabricated building consisting of multiple factory-made modules that are assembled on site. Unlike traditional “on-site built” homes, the various parts of a modular home are built about 80% to 90% in a controlled factory environment, then transported to the final location and quickly assembled into a complete home using equipment such as cranes. The completed modular home is no different from a traditional home in appearance, structure and durability, and must comply with local building regulations and safety standards.

2. Core advantages of modular housing

1. Fast construction

Since the modules are built in the factory at the same time as on-site preparation, the overall construction cycle is greatly shortened. Traditional home construction usually takes 9 to 12 months, while modular homes can be completed in 3 to 5 months, greatly meeting the needs of time-sensitive homebuyers. In addition, the factory environment avoids the impact of bad weather on construction and ensures stable progress.

2. Highly customized

Modular homes support a variety of designs and personalized customization. Homebuyers can choose different apartment types, styles, window locations, and even integrate smart home systems to remotely control functions such as lights and door locks. Manufacturers usually provide a wide range of decoration, equipment and material options to ensure that the home meets personal preferences.

3. Energy saving and environmental protection

Modular homes use high-efficiency insulation materials and structural designs, such as 2×6-inch wood frames and outer panels, which effectively improve insulation performance and reduce heating and cooling costs. The factory production process accurately controls the amount of materials used, reduces waste, and has significant environmental benefits.

4. Affordable

Due to factory assembly line production and large-scale material procurement, modular homes have more cost advantages than traditional on-site construction. The shortened construction period also reduces labor costs and loan interest expenses, making the overall home purchase cost more competitive.

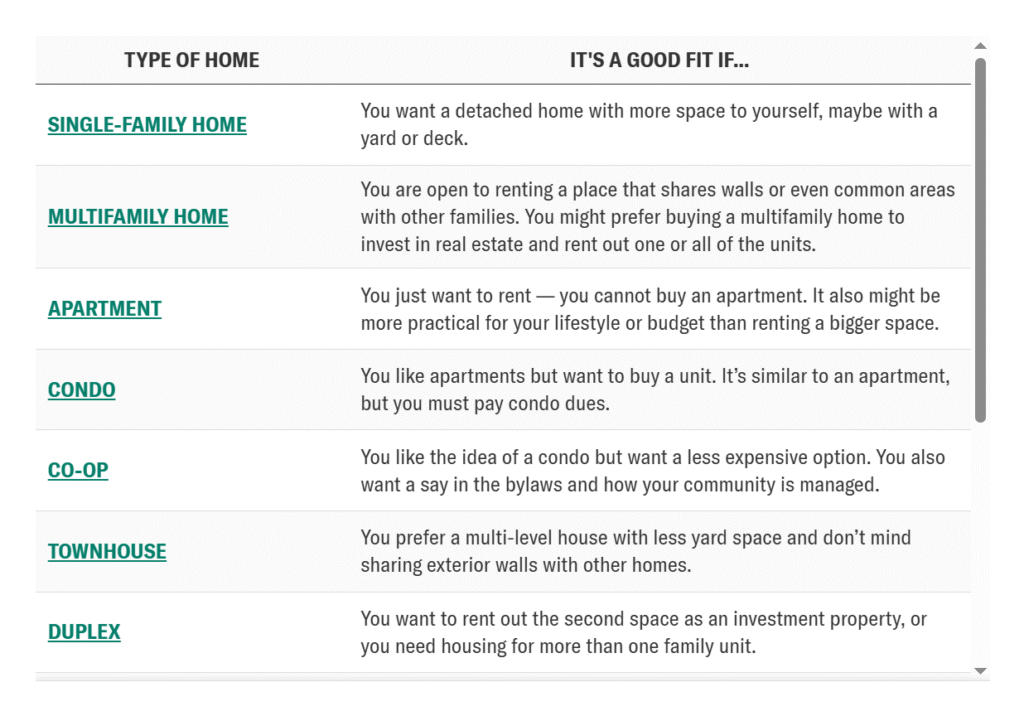

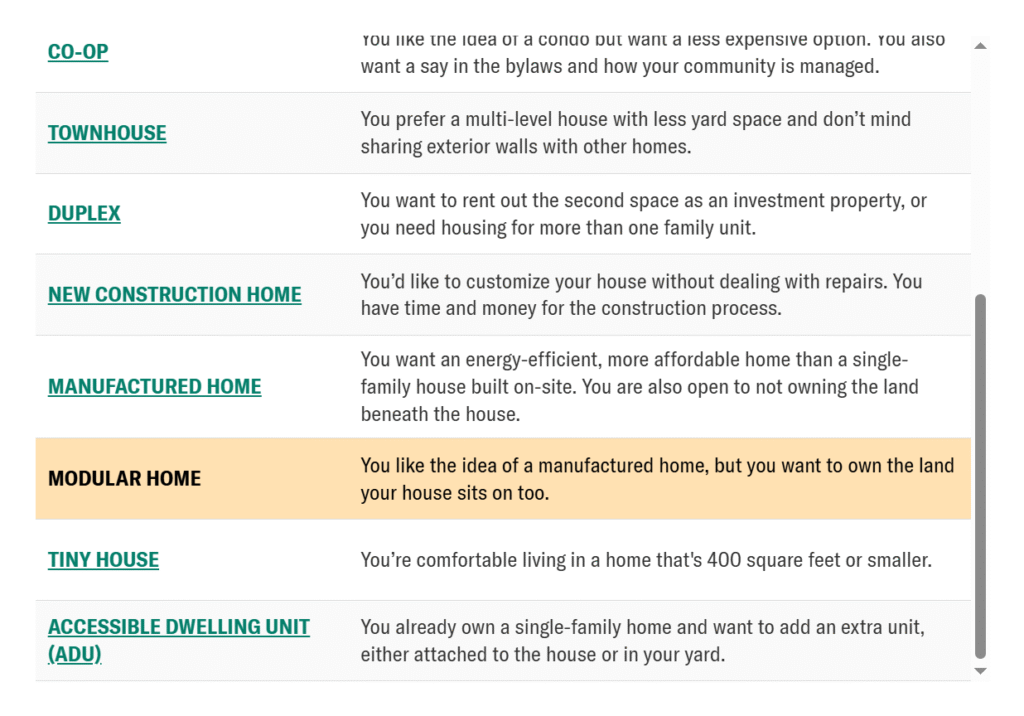

3. The difference between modular homes and manufactured homes

- Modular homes: Built according to local building specifications, the modules are manufactured in the factory and assembled on site, installed on a permanent foundation, and are permanent buildings.

- Manufactured housing (mobile home): manufactured in a factory, installed on a movable structure with a chassis, following the standards of the Federal Department of Housing and Urban Development (HUD), usually movable, and non-permanent buildings.

Modular housing is closer to traditional housing in terms of quality standards and durability, while manufactured housing is more flexible and portable.

4. Applicable scenarios and market trends

Modular housing is suitable for a variety of housing needs, including first-time homebuyers, expanding families, and downsizing. Its rapid construction and customization advantages make it attractive in both urban and remote areas, especially in a market environment that copes with labor shortages and rising construction costs. With technological advances and design innovations, modular housing is gradually becoming an important part of mainstream residential construction.

Modular housing combines factory prefabrication with rapid on-site assembly to provide an efficient, flexible and economical housing solution. It not only shortens the construction cycle and reduces costs, but also gives homebuyers a wide range of personalized choices. Different from traditional manufactured housing, modular housing has won market recognition for its permanence and high-standard quality. For homebuyers seeking a modern, eco-friendly, and functional home, modular homes are undoubtedly an ideal path to explore.